Technical Data

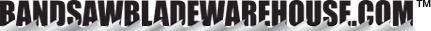

Tooth Pitch Recommendation for Solid Material

| D | tpi | D | tpi | D | tpi |

| < 10 mm | 14 | < 25 mm | 10/14 | 50 - 120 mm | 3/4 |

| 10 - 30 mm | 10 | 15 - 40 mm | 8/12 | 100 - 250 mm | 2/3 |

| 30 - 50 mm | 8 | 25 - 50 mm | 6/10 | 150 - 400 mm | 1,5/2 |

| 50 - 80 mm | 6 | 35 - 70 mm | 5/8 | 350 - 600 mm | 1,1/1,6 |

| 80 - 120 mm | 4 | 40 - 90 mm | 5/6 | > 500 mm | 0,85/1,15 |

| 120 - 200 mm | 3 | 50 - 120 mm | 4/6 | ||

| 200 - 300 mm | 2 | 80 - 150 mm | 3/4 | ||

| 300 - 700 mm | 1,25 | 130 - 350 mm | 2/3 | ||

| > 600 mm | 0,75 | 150 - 450 mm | 1,5/2 | ||

| 200 - 600 mm | 1,1/1,6 | ||||

| > 500 mm | 0,75/1,25 |

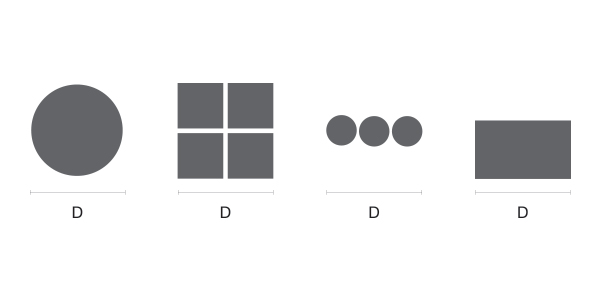

Tooth Pitch Recommendation for Tubes and Profiles

| Wall Thickness | ||||||||||

| S (mm) | 20 | 40 | 60 | 80 | 100 | 120 | 150 | 200 | 300 | 500 |

| 2 | 14 | 10/14 | 10/14 | 10/14 | 10/14 | 8/11P | 8/11P | 8/11P | 8/11P | 5/7P |

| 3 | 14 | 10/14 | 10/14 | 8/11P | 8/11P | 8/11P | 8/11P | 5/7P | 5/7P | 5/7P |

| 4 | 10/14 | 10/14 | 8/11P | 8/11P | 8/11P | 5/7P | 5/7P | 5/7P | 5/7P | 4/6P |

| 5 | 10/14 | 10/14 | 8/11P | 8/11P | 5/7P | 5/7P | 5/7P | 4/6P | 4/6P | 4/6P |

| 6 | 10/14 | 8/11P | 8/11P | 5/7P | 5/7P | 5/7P | 5/7P | 4/6P | 4/6P | 4/6P |

| 8 | 10/14 | 8/11P | 8/11P | 5/7P | 5/7P | 5/7P | 4/6P | 4/6P | 4/6P | 4/6P |

| 10 | 8/11P | 5/7P | 5/7P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | |

| 12 | 8/11P | 5/7P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | |

| 15 | 8/11P | 5/7P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | |

| 20 | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | 4/6P | 3/4P | ||

| 30 | 4/6P | 4/6P | 4/5P | 4/6P | 4/6P | 4/6P | 2/3P | |||

| 50 | 4/6P | 3/4P | 2/3P | 2/3P | ||||||

| 80 | 3/4P | 2/3P | 2/3P | |||||||

| > 100 | 2/3P | 1,5/2 |

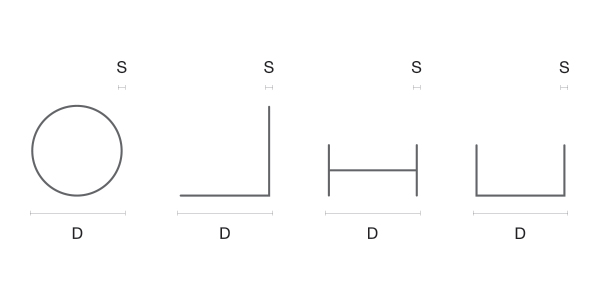

Break-In Procedures

Life-tie of band saw baldes mainly depends on a controlled break-in. We recommend the following break-in procedure:

- 1st Step: Select the correct speed Vc (m/min) and cutting rate Vz (cm/min) based on cutting conditions chart

- 2nd Step: You start with 70% of the regular cutting speed and 50% of the regular cutting rate

- 3rd Step: If vibrations still occur, change the speed carefully until the vibrations stop. A permananet chip formation is important during the whole cutting process.

- 4th Step: After cutting approx. 400-600 cm2 or at least 15 minutes real cutting time for tubes and profiles you can first slowly turn up to the final speed and then up to the normal cutting rate.

Cutting Rates

| Material | DIN | USA | JIS | Size mm | Size mm | Size mm | |||

| 27 x 0,9 - 34 x 1,1 Ø 50 - 350 cm |

41 x 1,3 - 54 x 1,6 Ø 100 - 500 cm |

67 x 1,6 - 80 x 1,6 Ø 400 - 2000 cm |

|||||||

| Vc (m/cm) | Vz (cm2) | Vc (m/cm) | Vz (cm2) | Vc (m/cm) | Vz (cm2) | ||||

| 1.0060 | St 60-2 | A 572 Gr.65 | SM 58 | 65 - 70 | 35 - 40 | 60 - 65 | 40 - 45 | 40 - 50 | 20 - 30 |

| 1.0401 | C15 | 1016 | S 15C | 65 - 70 | 35 - 40 | 60 - 65 | 40 - 45 | 40 - 50 | 20 - 30 |

| 1.0503 | C45 | 1045 | S 45C | 68 - 74 | 40 - 45 | 65 - 70 | 45 - 50 | 40 - 55 | 20 - 35 |

| 1.0570 | St52-3 | A572 Gr.50 | SM 490 | 68 - 74 | 40 - 45 | 65 - 70 | 45 - 50 | 40 - 55 | 20 - 35 |

| 1.1158 | Ck25 | 1025 | S25C | 68 - 74 | 40 - 45 | 60 - 70 | 45 - 50 | 40 - 55 | 20 - 30 |

| 1.1221 | Ck60 | 1060 | S58C | 68 - 74 | 40 - 45 | 60 - 70 | 40 - 45 | 35 - 45 | 15 - 25 |

| 1.2080 | X210 Cr 12 | D3 | SKD 1 | 33 - 37 | 10 - 18 | 25 - 35 | 15 - 20 | 15 - 20 | 05 - 10 |

| 1.2312 | 40CrMnMoS 8-6 | 49 - 53 | 22 - 30 | 45 - 50 | 28 - 32 | 25 - 30 | 10 - 15 | ||

| 1.2343 | X38 CrMoV 5-1 | H11 | SKD 6 | 41 - 45 | 18 - 24 | 36 - 40 | 22 - 26 | 22 - 30 | 10 - 20 |

| 1.2363 | X100 CrMoV 5-1 | A2 | SKD 12 | 38 - 42 | 15 - 20 | 30 - 36 | 18 - 22 | 20 - 26 | 08 - 14 |

| 1.2379 | X155 CrVMo 12-1 | D2 | SKD 11 | 33 - 37 | 10 - 18 | 25 - 35 | 15 - 20 | 15 - 20 | 05 - 10 |

| 1.2510 | 100 MnCrW4 | O1 | SKS 3 | 42 - 46 | 18 - 24 | 36 - 42 | 22 - 26 | 26 - 30 | 12 - 18 |

| 1.2606 | X37 CrMoW 5-1 | H12 | SKD 62 | 42 - 46 | 18 - 24 | 36 - 42 | 22 - 26 | 20 - 28 | 08 - 16 |

| 1.2714 | 56 NiCrMoV7 | L6 | SKT 4 | 42 - 46 | 20 - 26 | 40 - 45 | 25 - 30 | 26 - 34 | 12 - 18 |

| 1.2842 | 90 MnCrV 8 | O2 | 42 - 45 | 18 - 24 | 36 - 42 | 24 - 28 | 24 - 32 | 12 - 18 | |

| 1.3343 | S6-5-2 | M2 | SKH 51 | 36 - 40 | 16 - 20 | 30 - 35 | 16 - 20 | 26 - 30 | 12 - 18 |

| 1.3247 | S20-20-1-8 | M42 | SKH 59 | 36 - 40 | 16 - 20 | 30 - 35 | 16 - 20 | 26 - 30 | 12 - 18 |

| 1.3965 | X8 CrMnNi 18-8 | Nitronic 50 | 30 - 32 | 8 - 12 | 26 - 28 | 12 - 18 | 12 - 18 | 04 - 08 | |

| 1.4006 | X10 Cr 13 | SUS410 | 410 | 32 - 34 | 12 - 16 | 30 - 34 | 16 - 22 | 20 - 26 | 08 - 14 |

| 1.4028 | X20 Cr 13 | 420 | SUS 420 J1 | 36 - 38 | 15 - 20 | 32 - 36 | 18 - 22 | 26 - 30 | 06 - 10 |

| 1.4125 | X105 CrMo 17 | 440 C | SUS 440 C | 34 - 37 | 12 - 18 | 28 - 32 | 16 - 18 | 16 - 22 | 06 - 10 |

| 1.4301 | X5 CrNi 18-10 | 304 | SUS 304 | 36 - 38 | 15 - 20 | 32 - 36 | 18 - 22 | 16 - 22 | 06 - 10 |

| 1.4401 | X5 CrNiMo 17-12-2 | 316 | SUS 316 | 34 - 36 | 14 - 18 | 28 - 32 | 16 - 18 | 16 - 22 | 06 - 10 |

| 1.4462 | X2 VrNiMoN 22-5-3 | 2205 | SUS 329J3L | 32 - 34 | 10 - 14 | 28 - 32 | 16 - 20 | 16 - 22 | 06 - 10 |

| 1.4571 | X6 CrNiMoTi 17-12-2 | 316 Ti | SUS 316 | 32 - 34 | 10 - 14 | 28 - 32 | 16 - 20 | 16 - 22 | 06 - 10 |

| 1.4541 | X15 CrNiSi 25-20 | 314 | SUH 310 | 28 - 32 | 8 - 12 | 26 - 30 | 12 - 16 | 14 - 20 | 04 - 08 |

| 1.4864 | X12 NiCrSi 26-16 | 330 | SUH 330 | 28 - 32 | 8 - 12 | 26 - 30 | 12 - 16 | 14 - 20 | 04 - 08 |

| 1.4923 | X22 CrMoV 12-1 | 28 - 32 | 8 - 12 | 26 - 30 | 12 - 16 | 14 - 20 | 04 - 08 | ||

| 1.4980 | X5 NiCrTi 26-15 | A286 | SUH 660 | 28 - 32 | 8 - 12 | 26 - 30 | 12 - 16 | 14 - 20 | 04 - 08 |

| 1.5710 | 36 NiCr 6 | (X)3140 | 48 - 52 | 22 - 28 | 44 - 48 | 28 - 32 | 26 - 34 | 12 - 18 | |

| 1.5755 | 31 NiCr 14 | 3415 | SNC 815 | 50 - 54 | 24 - 30 | 46 - 52 | 30 - 36 | 30 - 36 | 14 - 20 |

| 1.6310 | 20 MnMoN i-5 | 48 - 52 | 22 - 28 | 44 - 48 | 28 - 32 | 26 - 34 | 12 - 18 | ||

| 1.6523 | 20 NiCrMo 2 | 8620 | SNCM 220 | 50 - 54 | 24 - 30 | 44 - 50 | 30 - 34 | 26 - 34 | 14 - 20 |

| 1.6546 | 40 NiCrMo 2-2 | 8640 | SNCM 240 | 50 - 54 | 24 - 30 | 44 - 50 | 30 - 34 | 30 - 34 | 10 - 18 |

| 1.6562 | 40 NiCrMo 7 | E4340 | SNB24-15 | 50 - 54 | 24 - 30 | 44 - 50 | 30 - 34 | 30 - 34 | 10 - 18 |

| 1.6749 | 23 CrNiMo 7-4-7 | 50 - 54 | 24 - 28 | 44 - 50 | 28 - 32 | 30 - 34 | 10 - 16 | ||

| 1.6985 | 28 CrMoNiV 4-9 | 54 - 58 | 28 - 34 | 48 - 54 | 32 - 38 | 36 - 40 | 16 - 22 | ||

| 1.7147 | 20 MnCr 5 | SmnC420H | 5120 | 58 - 62 | 28 - 36 | 52 - 56 | 32 - 38 | 38 - 46 | 18 - 26 |

| 1.7225 | 42 CrMo 4 | 4140 | SCM 440 | 54 - 58 | 28 - 34 | 48 - 54 | 32 - 38 | 36 - 40 | 16 - 22 |

| 1.7228 | 50 CrMo 4 | 4250 | SCM 445 | 56 - 60 | 30 - 36 | 52 - 56 | 34 - 40 | 34 - 40 | 16 - 20 |

| 1.7335 | 13 CrMo 4-4 | SFVA F 12 | A387 Gr. 12 | 62 - 64 | 32 - 38 | 56 - 60 | 36 - 44 | 40 - 46 | 18 - 26 |

| 1.7707 | 30 CrMoV 9 | 54 - 58 | 28 - 34 | 44 - 50 | 28 - 34 | 28 - 34 | 16 - 20 | ||

| 1.8159 | 50 CrV 4 | 6150 | SUP10 | 52 - 54 | 24 - 30 | 52 - 48 | 32 - 38 | 32 - 40 | 12 - 20 |

| 1.8509 | 41 CrAlMo 7 | A 355 CI. A | SACM 645 | 42 - 45 | 18 - 24 | 36 - 40 | 22 - 26 | 18 - 24 | 08 - 14 |

Above cutting chart refers to average settings. Figures might differ depending on blade type, band saw machine type, condition of thematerial to be cut (surface, heat treatment, standard, ...) and the required cutting specification (tolerances, service life, ...). Please notice that the ultimate service life can only be achieved after correct break-in. If your material is not listed please do not hesitate to contact us for further information.